In today’s fast-paced manufacturing world, CNC (Computer Numerical Control) machines play a crucial role in producing precise and complex parts. CNC machines have revolutionized the manufacturing industry by offering automation, precision, and efficiency. In this blog, we’ll explore the various types of CNC machines, shedding light on their unique capabilities and applications. Understanding these different types can help businesses make informed decisions when choosing the right CNC machine for their specific needs.

1. CNC Milling Machines

CNC milling machines are among the most common types of CNC machines. These machines use rotating cutting tools to remove material from a workpiece, creating complex shapes and features. CNC milling machines are highly versatile and can perform a range of operations, including drilling, boring, and threading. They are used in industries such as aerospace, automotive, and electronics for creating parts like engine components, molds, and circuit boards.

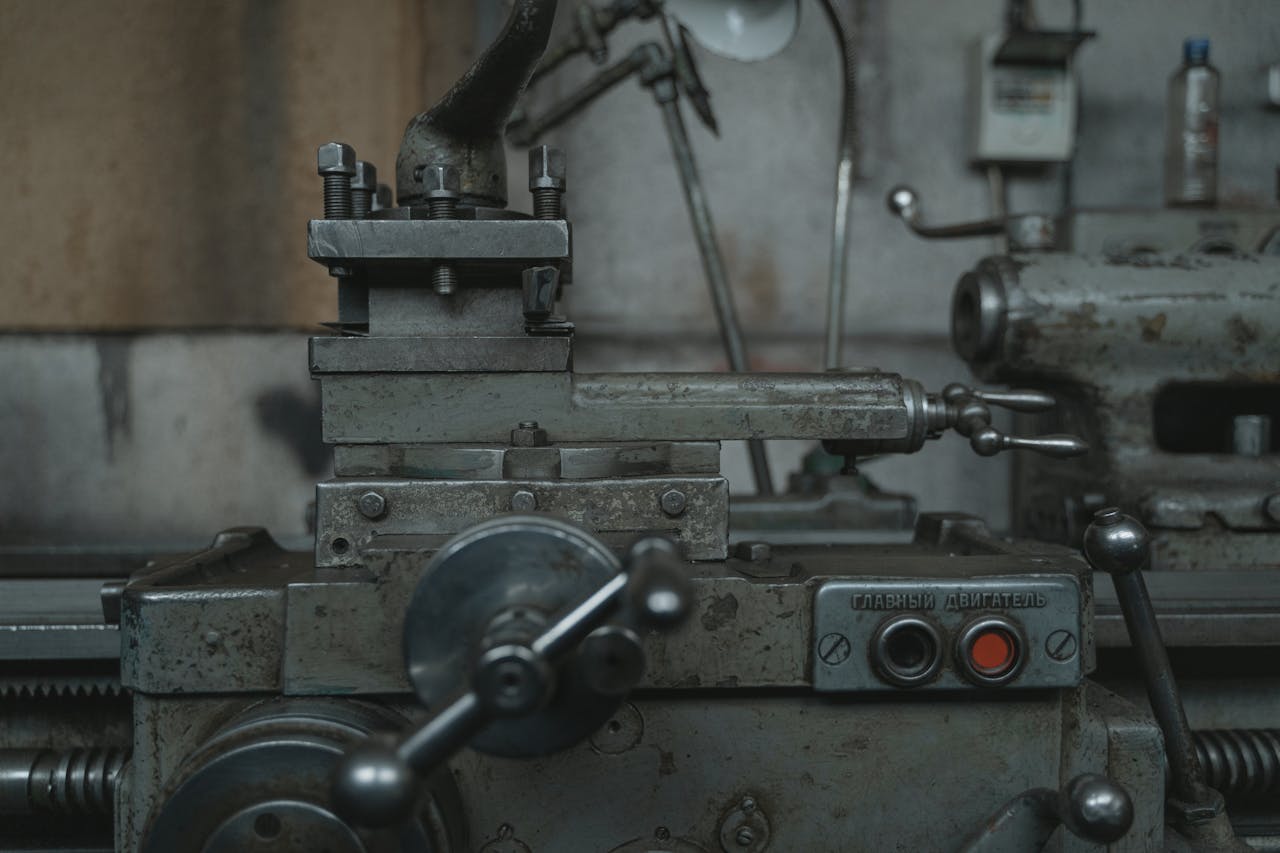

2. CNC Lathes

CNC lathes are designed for machining cylindrical or symmetrical parts. They work by rotating the workpiece while a stationary cutting tool shapes the material. CNC lathes are ideal for producing parts with rotational symmetry, such as shafts, bushings, and pulleys. These machines are widely used in industries like automotive, oil and gas, and metalworking.

3. CNC Plasma Cutters

CNC plasma cutters utilize a high-velocity jet of ionized gas (plasma) to cut through conductive materials like steel, aluminum, and brass. These machines are known for their speed and precision, making them suitable for cutting intricate shapes and patterns. CNC plasma cutters are commonly used in industries such as metal fabrication, automotive repair, and construction.

4. CNC Laser Cutters

CNC laser cutters employ a focused laser beam to cut or engrave materials with exceptional precision. These machines can cut through a variety of materials, including metals, plastics, wood, and textiles. CNC laser cutters are widely used in industries like aerospace, electronics, and signage for applications such as cutting intricate designs, engraving, and marking.

5. CNC Electrical Discharge Machines (EDM)

CNC EDM machines use electrical discharges (sparks) to erode material from a workpiece. There are two main types of CNC EDM machines: wire EDM and sinker EDM. Wire EDM uses a thin wire to cut through the material, while sinker EDM uses an electrode to create complex shapes. These machines are ideal for producing intricate and delicate parts, such as molds, dies, and medical devices.

6. CNC Routers

CNC routers are used for cutting, shaping, and engraving materials like wood, plastics, and composites. They are similar to CNC milling machines but are typically used for larger, flat workpieces. CNC routers are popular in industries like woodworking, furniture manufacturing, and sign-making. They are used to create items such as cabinetry, furniture components, and custom signs.

7. CNC Grinders

CNC grinders use abrasive wheels to remove material and create a smooth finish on a workpiece. These machines are essential for achieving high precision and fine surface finishes. CNC grinders are commonly used in industries such as aerospace, automotive, and tool and die making. They are used to produce parts like gears, bearings, and cutting tools.

8. CNC Drilling Machines

CNC drilling machines are specifically designed for creating precise holes in a workpiece. These machines can drill holes of various sizes and depths with high accuracy. CNC drilling machines are used in industries like construction, electronics, and manufacturing for applications such as creating circuit boards, structural components, and mechanical parts.

Conclusion

CNC machines have revolutionized modern manufacturing by providing unmatched precision, efficiency, and versatility. Understanding the different types of CNC machines and their applications can help businesses choose the right equipment for their specific needs. Whether it’s CNC milling machines, lathes, plasma cutters, or laser cutters, each type of CNC machine offers unique capabilities that contribute to the overall success of manufacturing processes. Investing in the right CNC technology can significantly enhance productivity, reduce costs, and improve the quality of finished products.

By incorporating these keywords and focusing on the unique benefits and applications of each type of CNC machine, this blog aims to improve SEO and attract readers interested in CNC technology.