Engaging Introductions: Capturing Your Audience’s Interest

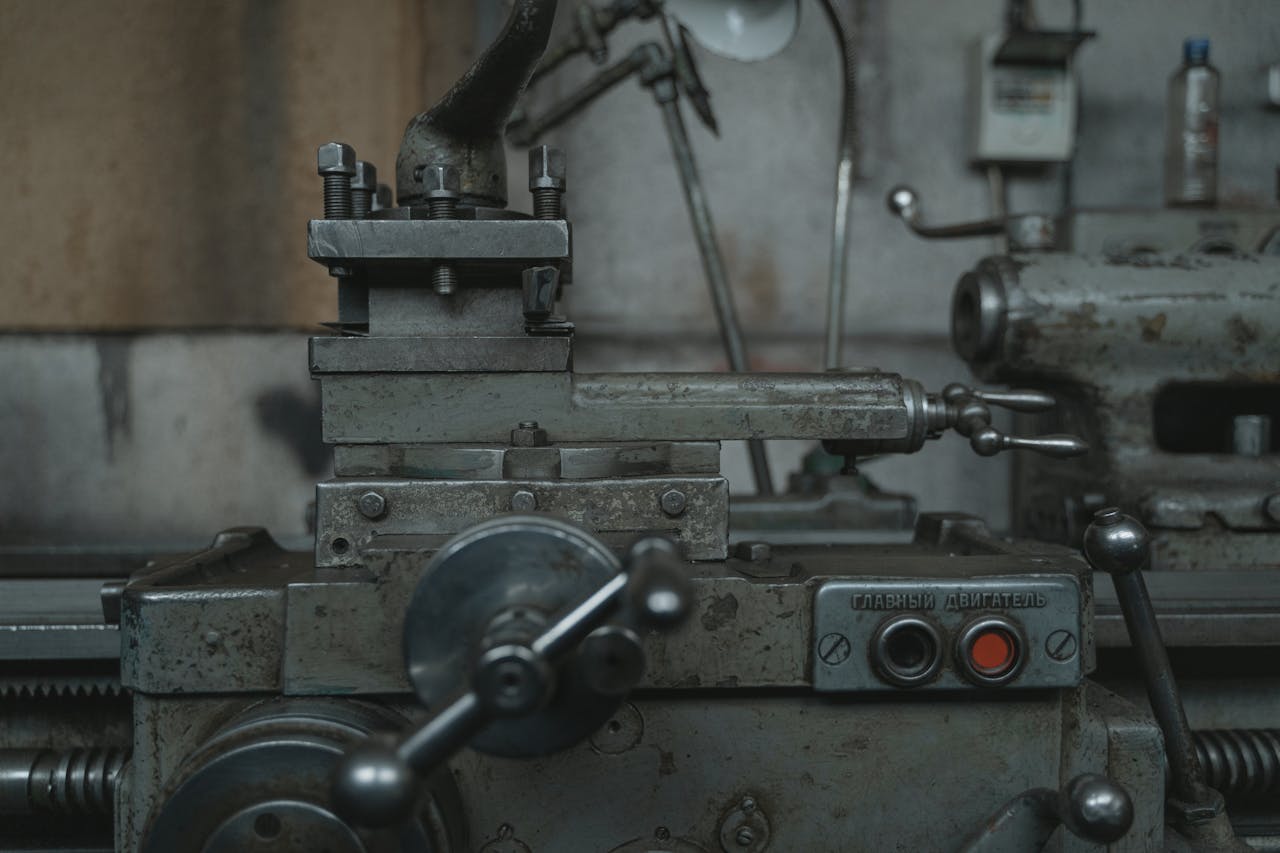

In the ever-evolving landscape of modern manufacturing, precision, efficiency, and innovation are paramount. One of the most transformative advancements in this realm is the integration of CNC (Computer Numerical Control) machines. These sophisticated devices have revolutionized the way manufacturers produce goods, offering a plethora of benefits that enhance productivity and quality. In this blog, we’ll delve into the myriad advantages of CNC machines and why they have become indispensable in contemporary manufacturing.

1. Unmatched Precision and Consistency

CNC machines are renowned for their ability to produce highly precise and consistent parts. Unlike manual machining, where human error can lead to inconsistencies, CNC machines follow programmed instructions to the letter. This ensures that each part produced is identical to the specifications, significantly reducing the margin of error. This level of precision is crucial in industries where exact measurements are essential, such as aerospace, automotive, and medical device manufacturing.

2. Enhanced Efficiency and Speed

One of the primary advantages of CNC machines is their ability to operate continuously with minimal supervision. Once the machine is programmed and set up, it can run 24/7, significantly boosting production rates. This continuous operation not only increases output but also reduces lead times, enabling manufacturers to meet tight deadlines and respond swiftly to market demands.

3. Versatility and Flexibility

CNC machines are incredibly versatile, and capable of performing a wide range of tasks, including milling, turning, drilling, and cutting. This versatility allows manufacturers to use a single machine for multiple operations, streamlining the production process. Additionally, CNC machines can be quickly reprogrammed to produce different parts, offering flexibility in responding to changing production requirements and custom orders.

4. Cost-Effectiveness

While the initial investment in CNC machines can be substantial, the long-term cost savings are significant. The increased efficiency and reduced waste associated with CNC machining lead to lower production costs. Moreover, the ability to produce parts with high precision minimizes the need for rework and scrap, further driving down costs. Over time, the return on investment for CNC machines can be substantial, making them a cost-effective choice for manufacturers.

5. Improved Safety

Safety is a critical concern in manufacturing environments. CNC machines enhance safety by reducing the need for human intervention in potentially hazardous tasks. Operators can program the machine from a safe distance, minimizing the risk of accidents. Additionally, modern CNC machines are equipped with safety features such as automatic shut-offs and emergency stops, further ensuring a safe working environment.

6. Superior Quality Control

CNC machines are equipped with advanced software that allows for real-time monitoring and quality control. This capability ensures that any deviations from the specified parameters are detected and corrected immediately. As a result, manufacturers can maintain stringent quality standards, producing parts that meet or exceed industry specifications. This level of quality control is particularly important in industries where precision and reliability are non-negotiable.

7. Environmental Benefits

Sustainability is becoming increasingly important in manufacturing. CNC machines contribute to environmental sustainability by reducing material waste and optimizing energy usage. The precision of CNC machining means that materials are used more efficiently, minimizing excess and scrap. Additionally, the automation and efficiency of CNC machines can lead to lower energy consumption compared to traditional manual machining processes.

Conclusion

The integration of CNC machines in modern manufacturing has brought about a paradigm shift, offering unprecedented levels of precision, efficiency, and versatility. These machines have not only enhanced productivity but also improved safety, quality control, and sustainability. As the manufacturing industry continues to evolve, CNC machines will undoubtedly play a pivotal role in driving innovation and maintaining competitive advantage. For manufacturers looking to stay ahead in a rapidly changing market, investing in CNC technology is a strategic move that promises significant long-term benefits.